What Is Curing Of Concrete

How Curing Is Done In Cement Concrete

In this post I am sharing my knowledge regarding How curing is done in concrete and what is curing actually and how cement concrete exactly works when curing is done.In this article you will get info about how curing effects the properties of concrete what is curing in concrete curing in concrete definition and what is curing in construction.

Curing Of Concrete:

Curing Definition

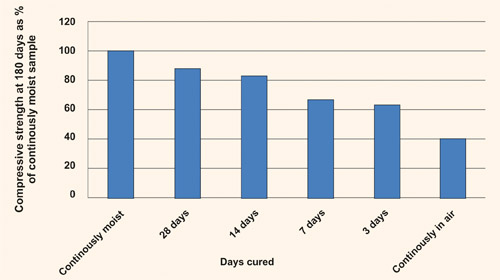

Curing is the process in which the concrete is protected from loss of moisture and kept within a reasonable temperature range. The result of this process is increased strength and decreased permeability. Curing is also a key player in mitigating cracks in the concrete, which severely impacts durability. The figure is self explanatory, the amount of strength desired is related to the duration of curing.

Curing may be defined as the process of maintaining satisfactory moisture and temperature conditions for freshly placed concrete for some specified time for proper hardening of concrete. Curing in the early ages of concrete is more important. Curing for 14 days is very important. Better to continue it for 7 to 14 days more. If curing is not done properly, the strength of concrete reduces. Cracks develop due shrinkage.The durability of concrete structure reduces.

Curing Of Concrete As per IS 456 - 2000

The Indian Standard IS 456 – 2000 recommends that curing duration of concrete must be at least 7 days in case of ordinary Portland Cement, at least 10 days for concrete with mineral admixtures or blended cements are used. It also recommends that the curing duration should not be less than 10 days for concrete exposed to dry and hot weather conditions and 14 days for concrete with mineral admixtures or blended cement in hot and dry weather.

Minimum Curing time for Concrete to attain maximum strength is 28 days if you are using 33 grade Cement of ISI-269 , 43 grade Cement of ISI -8112 and Fly Ash Based Cement ISI- 1489. But if You are using 53 grade Cement of ISI-12269 Concrete will attain maximum strength in 14 days and water sprinkling to be continued for 30 days. In Summer 50% of the water using for curing the concrete will evaporate and Curing will not be sufficient to keep the concrete in Cool condition. So wrap the concrete with Gunny Bags and sprinkling of water to be done three times in Night up to 11 pm. Especially for 53 grade cement concrete we are following this method. Heat will get generated in concrete because of the Chemical Reaction happening in Concrete. To reduce the heat we are doing water Ponding above Slab and sprinkling water for other concrete. 53 grade concrete will Generate More Heat, So curing in day and night up to 11pm only will serve the purpose.

Methods Of Curing:

The following curing methods are employed:

(a) Spraying of water

(b) Covering the surface with wet gunny bags, straw etc.

(c) Ponding

(d) Steam curing and

(e) Application of curing compounds.

(a) Spraying of water: Walls, columns, plastered surfaces are cured by sprinkling water.

(b) Wet covering the surface: Columns and other vertical surfaces may be cured by covering the surfaces with wet gunny bags or straw.

(c) Ponding: The horizontal surfaces like slab and floors are cured by stagnating the water to a height of 25 to 50 mm by providing temporary small hunds with mortar.

(d) Steam curing: In the manufacture of pre-fabricated concrete units steam is passed over the units kept in closed chambers. It accelerates curing process, resulting into the reduction of curing period.

(e) Application of curing compounds: Compounds like calcium chloride may be applied on the curing surface. The compound shows affinity to the moisture and retains it on the surface. It keeps the concrete surface wet for a long time.

Why Curing Is Important In Construction

There are several important reasons why one should cure concrete:

Importance Of Curing In Civil Engineering

Advantages Of Curing:

- Concrete strength gain - Concrete strength increase with age as moisture and a favorable temperature is present for hydration of cement. An experimental investigation was conducted by "Cement, Concrete & Aggregates Australia" (CCAA) and the same was published in their data sheet on "Curing of Concrete," which has been included in this article for reference. Figure-1 illustrates a comparison of the strength of concrete at 180 days of moist curing with various periods of moist curing (0, 3, 7, 14 & 28 days) and then allowing it to dry out. From the graph below, it can be observed that concrete allowed to dry out immediately, achieves only 40% of the strength of the same concrete water cured for the full period of 180 days.

- Improved durability of concrete – The durability of concrete is affected by a number of factors including its permeability, porosity and absorptivity. Well cured concrete can minimize thermal, plastic & drying shrinkage cracks, making concrete more water tight, thus preventing moisture and water borne chemicals from entering into the concrete and thereby increasing its durability.

- Enhanced serviceability - Concrete that is allowed to dry out quickly undergoes considerable early age shrinkage. Inadequate curing contributes to weak and dusty surfaces having a poor abrasion resistance.

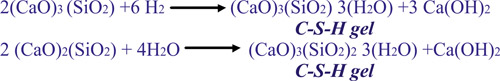

- Improved microstructure - Material properties are directly related to their microstructure. Curing assists the cement hydration reaction to progress steadily and develops calcium silicate hydrate gel, which binds the aggregates leading to a rock solid mass, makes the concrete denser, decreases the porosity and enhances the physical and mechanical properties of concrete.

Duration Of Curing:

The duration of curing of concrete depends on the grade & type of cement, mix proportion, desired concrete strength, shape and size of the concrete member and environmental & exposure conditions. The duration may vary from few days to a month.

IS-456:2000 provisions for duration of Curing (Indian Standard-Plain & Reinforced concrete-Code of Practice, 4th revision, page 27)

Exposed surfaces of concrete shall be kept continuously damp or in a wet condition by ponding or by covering with sacks, canvas, hessian or other similar material and kept continuously wet for atleast 7 days from the date of placing, in case of Ordinary Portland Cement (OPC) and atleast 10 days when mineral admixtures or blended cements are used. In case of concrete where mineral admixtures or blended cements are used, it is recommended that the above minimum periods may be extended to 14 days, for assisting the secondary reaction.

References:

- "Cement, Concrete & Aggregates Australia" (CCAA), Data sheet, April 2006, pages 1-7.

- "National Ready Mixed Concrete Association" (NRMCA), Data sheet, CIP-11-Curing In Place Concrete, pages 1&2.

- Kosmatka Steven H, Kerkhoff Beatrixa & Panarese William C, "Design and Control of Concrete Mixtures", EB001, 14th edition, Portland Cement Association, pages 219-223.

- Vincent T. H. CHU, "A Closer Look at Prevailing Civil Engineering Practice – What, Why and How?"

- Builder 3&2 Volume 01 – "Construction manual for building structures"

- D.M. Roy, G.M. Idorn, "Concrete Microstructure" Strategic Highway Research Program, National Research Council, Washington, DC 1993.

- IS 456:2000, Indian Standard-"Plain & Reinforced concrete-Code of Practice", 4th revision, page 27.

No comments